Fittings

Concentric and Eccentric Reducers

Concentric and Eccentric Reducers

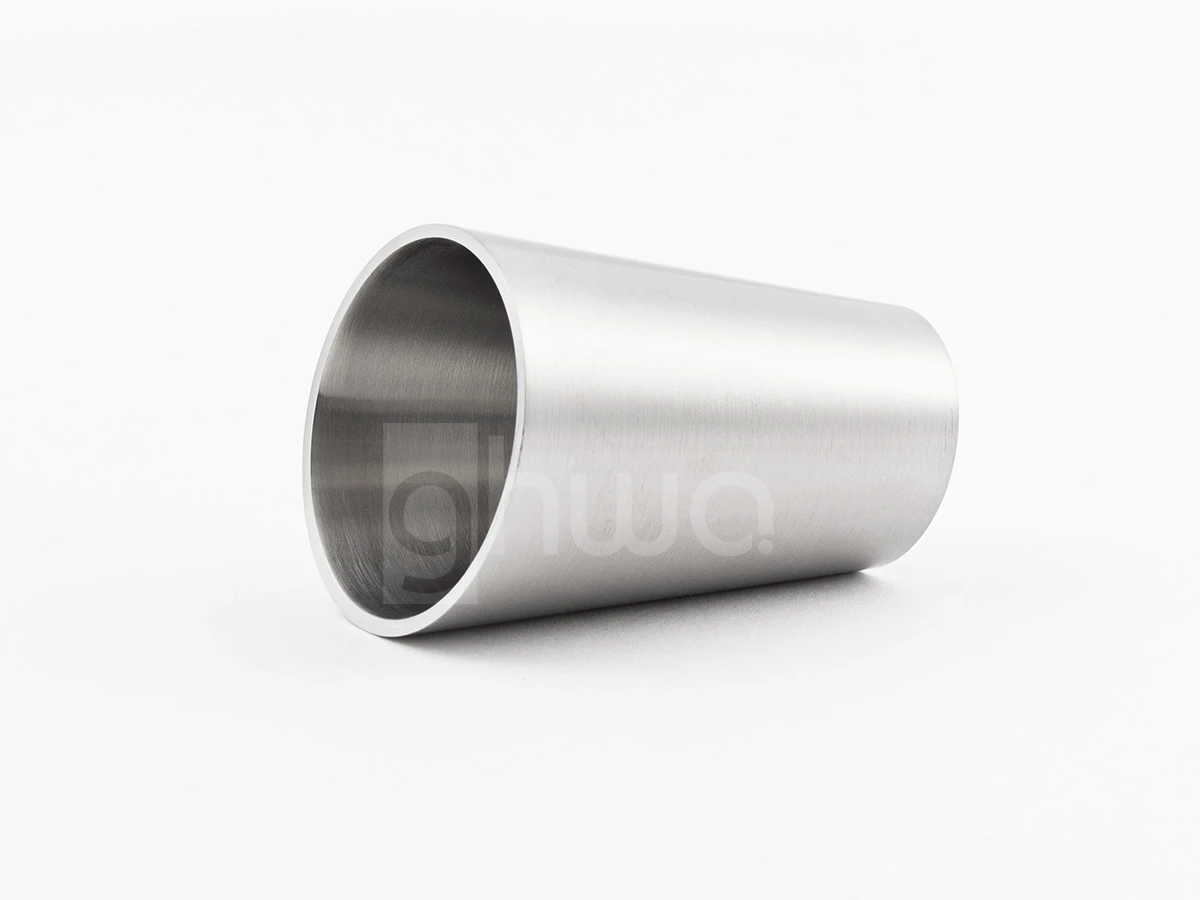

Stainless steel reducers are essential components in piping systems, enabling the transition between varying pipe sizes while promoting efficient flow and reducing turbulence. Widely used in sectors such as food processing, chemical manufacturing, pharmaceuticals, and industrial piping, these reducers contribute to improved performance and safety.

Available in multiple configurations tailored to specific applications, they are engineered to ensure reliable performance in both hygienic and industrial settings. Each type is built with attention to precision, durability, and compatibility with diverse piping requirements.

Products

Material:

SS304/ SS304L and SS316/ SS316L stainless steel, which has excellent corrosion resistance and mechanical strength, suitable for food, beverage and pharmaceutical production environments.

Size:

1/2” to 6” "(Subject to product specifications)

Connection:

Weld Type/ Clamp Type

Standard:

3-A, SMS, BS, AS, DIN and ASME BPE

Concentric Reducer

Designed with an offset centerline, eccentric reducers prevent air accumulation in horizontal piping, making them suitable for pump suction lines and applications requiring continuous flow.

Eccentric Reducer

Designed with an offset centerline, eccentric reducers prevent air accumulation in horizontal piping, making them suitable for pump suction lines and applications requiring continuous flow.

Reducers with Tangents

These reducers feature straight pipe lengths (tangents) on either end, simplifying welding and installation. They also help maintain laminar flow in sanitary and process piping.

SMS Reducers with Straight End

Compliant with SMS standards, these reducers offer a hygienic design suitable for dairy, food, and beverage processing industries. The straight ends allow for seamless integration with other SMS components.

WW, CW, and CC Reducers

Custom-engineered for specific operational environments:

- WW (Weld-Weld): Both ends prepared for butt welding.

- CW (Clamp-Weld): One end clamped for easy disassembly, the other end weldable.

- CC (Clamp-Clamp): Both ends equipped with sanitary clamps for quick installation and removal.