Miscellaneous

Clamps

Clamps

Clamps are critical components for establishing secure and leak-proof connections between pipes and fittings in production systems. Designed to meet the stringent requirements of hygiene-sensitive industries, clamps are widely used in food processing, pharmaceutical, and cosmetics manufacturing. They contribute to operational efficiency by enabling quick assembly and disassembly, facilitating maintenance and cleaning processes.

Clamps are compatible with a wide range of hygienic piping systems and are commonly applied across product lines conforming to 3-A, ASME BPE, and DIN standards.

Products

Material:

SS304 stainless steel, which has excellent corrosion resistance and mechanical strength, suitable for food, beverage and pharmaceutical production environments.

Size:

1/2" - 12" (Subject to product specifications)

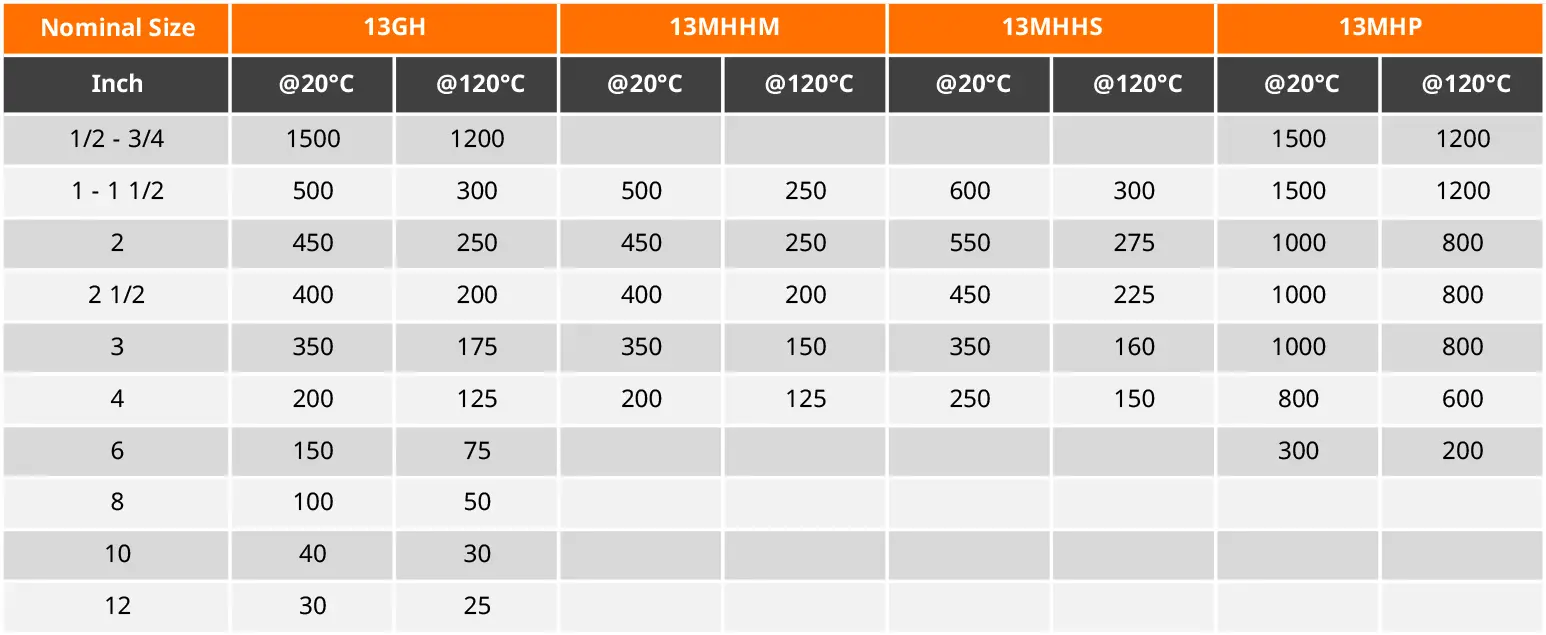

Recommended Max. PSI Service Ratings for Clamps:

*All ratings are dependent upon related components in the system and proper installation.

SS304 13GH Single Pin Heavy Duty Clamp

Heavy-duty clamp with single pin design. Made from SS304. Suitable for 3-A sanitary fittings. Easy installation and strong sealing.

Single Pin Heavy Duty Clamp #11

Wing Nut

Single Pin Heavy Duty Clamp #12

Wing Nut

Single Pin Heavy Duty Clamp #14

Wing Nut

Double Pin Heavy Duty Clamp #14 Wing Nut

SS304 13MHP High Pressure Bolted Clamp

Bolted clamp for high-pressure applications. Constructed from SS304. Meets 3-A standards. Provides secure and leak-proof connection.

High Pressure Clamp

SS304 13MHHS Three Segment Clamp

Three-segment clamp made of SS304. Designed for large diameter fittings. Ensures even pressure and stable connection. Suitable for 3-A systems.

Three Segment Clamp #14 Wing Nut

Advantages

Easy to install and remove:

Cost and time efficient:

Adjustable without permanent welding:

Good resistance to vibration:

Versatile for various applications:

Applications of Clamps

- Used to connect sanitary fittings in processing pipelines for food, dairy, and beverage production.

- Applied in clean-in-place (CIP) and steam-in-place (SIP) systems to allow easy disassembly for cleaning.

- Installed in pharmaceutical and biotech facilities for secure, contamination-free connections.

- Used in modular systems where frequent adjustment or expansion of pipelines is required.

- Ideal for assembling filter housings, valves, and tanks with sanitary fittings.

- Suitable for transferring liquids in high-purity environments under hygienic standards.

- Commonly used in temporary setups during system testing or process validation.

- Supports flexible layout designs in stainless steel piping systems without welding.

- Enables quick changeover between production lines or product batches.

- Facilitates maintenance by allowing tool-free access to internal components.