Tubes

Food Grade Stainless Steel Tube

Food Grade Stainless Steel Tube

SMS Standard / 3-A Standard

Stainless steel tubes built to food-grade standards are the backbone of hygienic piping systems. These tubes are used for transporting liquids and gases in industries where contamination control is vital. Available in SMS and 3-A standards, they cater to both European and American regulatory frameworks.

SMS Standard Stainless Steel Tube

Products

Metric-based tube dimensions commonly used in European processing systems. Designed with a hygienic ID finish suitable for food and beverage industries.

Material:

SS304/ SS304L and SS316/ SS316L stainless steel, offering excellent corrosion resistance and mechanical strength, suitable for hygienic processing environments.

Size:

25.4 mm – 101.6 mm OD (see below)

Surface:

Polished internal/external surface (Ra ≤ 0.8 µm)

Standards:

SMS

Advantages

- Designed to comply with European sanitary piping standards

- Metric dimensions compatible with EU equipment

- Precision-polished internal surface ensures hygienic flow

- Excellent corrosion resistance for food, beverage, and pharmaceutical use

- Supports CIP cleaning systems, easy to weld and fabricate

- Full material traceability with MTRs available

Applications SMS Standard Stainless Steel Tube

Sanitary pipelines in dairy, brewery, and beverage plants

CIP loops

Pharmaceutical and cosmetic fluid transfer systems

Cleanroom and aseptic processing lines

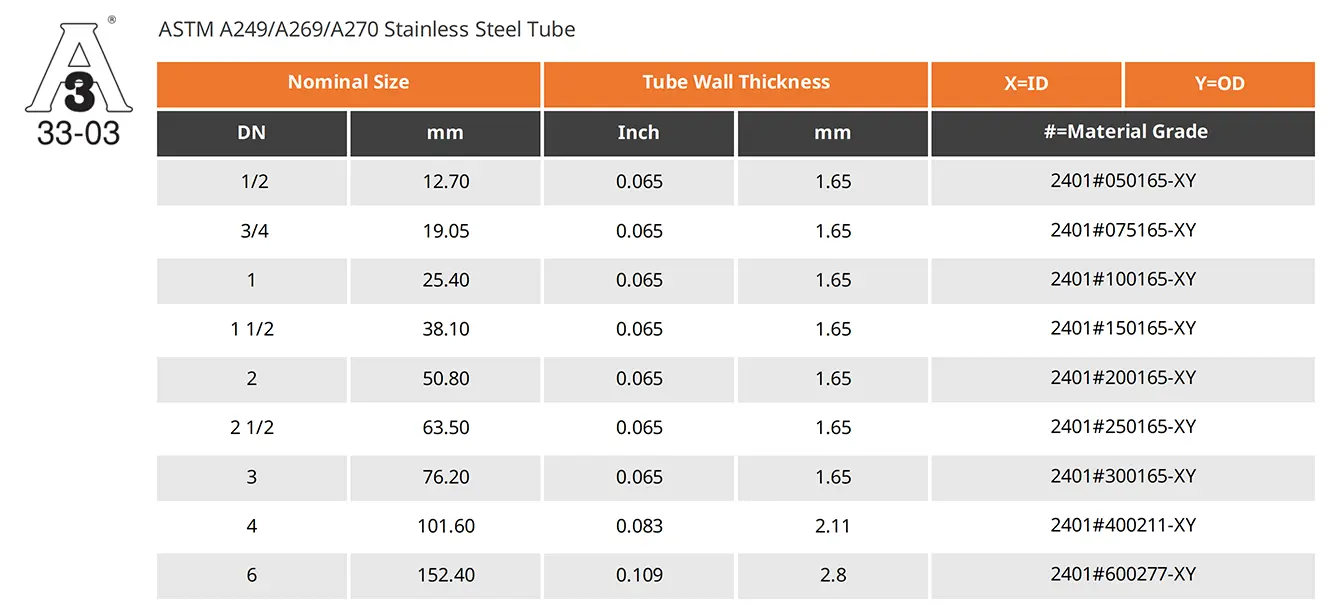

3-A Standard Stainless Steel Tube

Products

Imperial-based tubing system widely accepted in American markets. Built to meet stringent 3-A Sanitary Standards for dairy, food, and pharmaceutical use.

Material:

SS304/ SS304L and SS316/ SS316L stainless steel, engineered for high durability and corrosion resistance in critical hygiene applications.

Size:

½” – 6” OD (see below)

Surface:

Polished internal/external surface (Ra ≤ 0.8 µm)

Standards:

3A

Advantages

- Complies with strict 3-A Sanitary Standards for hygienic processing

- Smooth internal finish reduces risk of contamination

- Ideal for dairy, food, beverage, and biotech industries

- CIP-compatible with excellent weldability and cleanability

- Certified materials with full traceability and MTR documentation