Applications

E-Pharma DTS Shell & Tube Heat Exchanger meets the hygienic demands of the pharmaceutical industry, the heat exchanger was designed to work under the highest hygienic applications such as Water-For-Injection (WFI), Purified Water (PW) and heating/cooling of pharmaceutical fluid products.

The Principles and Workings of DTS Shell & Tube Heat Exchanger

The product media flows through a bundle of seamless polished tubes, the service media flows on the outside of the tubes in a cross flow, the tubes are fastened by two tube-sheets acting as leakage indicators at both ends, preventing cross contamination between the product and service media.

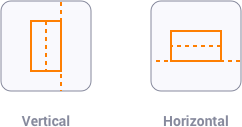

The heat exchanger can be installed horizontally or vertically depending on the duty or space. Thermal fatigue caused by large temperature changes is managed by expansion connection in straight units.

Features and Benefits

- 100% imported seamless tubes

- Double tube-sheets to prevent cross contamination

- Completely drainable on product side and easy to clean

- No dead leg in tubes

- Designed according to FDA and cGMP requirements

- Flexible in design

- Full documentation provided as standard

Over 20 Years of Innovative Solutions

Contact us today to learn more